Resources

Damper Inspection

May 20, 2020 Dampers are the single most effective way to protect duct and air transfer openings in building walls, corridors, barriers, partitions and shafts. But if the dampers in your facility don’t work as designed, you need to know!

Dampers are the single most effective way to protect duct and air transfer openings in building walls, corridors, barriers, partitions and shafts. But if the dampers in your facility don’t work as designed, you need to know!

While initial testing is essential to ensure proper operation following installation, it’s critical that facilities managers periodically inspect dampers throughout their facility to ensure they can continue functioning efficiently in the future. To make sure you’re in the know when it comes to what to look for, consider following a damper inspection plan.

What is a Damper Inspection Plan?

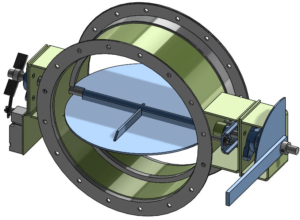

![]() Dampers inspections are important to the safety of your building. Inspections should follow a regular maintenance schedule – at least every few years – to ensure efficient operation. Inspection and maintenance requirements are defined by damper manufacturers such as Kelair and, in the case of fire and explosion proof dampers, by UL and the National Fire Protection Association (NFPA).

Dampers inspections are important to the safety of your building. Inspections should follow a regular maintenance schedule – at least every few years – to ensure efficient operation. Inspection and maintenance requirements are defined by damper manufacturers such as Kelair and, in the case of fire and explosion proof dampers, by UL and the National Fire Protection Association (NFPA).

Dampers can be subject to poor installation, corrosion, blockages and impediments, cumulative dust, microbial growth and mechanical failure. If you are concerned about the integrity of dampers used within your buildings, the following checklist provides a solid starting point for inspecting and assessing the quality of the dampers used at your facility.

- Do dampers fully close (automatically) from the open position? Fusible links need to be removed and reinstalled after tests are completed.

- Do damper latches and other components need to be checked/evaluated and moving parts lubricated.

- Is system airflow in dynamic dampers verified to be within the velocity rating from the damper manufacturer?

- Is there any obstruction in the damper that would prevent it, or any of its components, from operating as designed?

- Is the fusible link operating temperature in accordance with fire safety codes such as NFPA-90A?

- Are indicating devices of the damper working and reporting to the intended location?

- Was the inspecting and testing documented with the location of the damper, the date of inspection, name of inspector, deficiencies discovered and how they were resolved?