Industrial Grade Dampers For Paper Mill Pollution

Optimize the Air Handling Efficiency of Your Facility with Kelair Dampers

Download our BrochureKelair Dampers Brochure

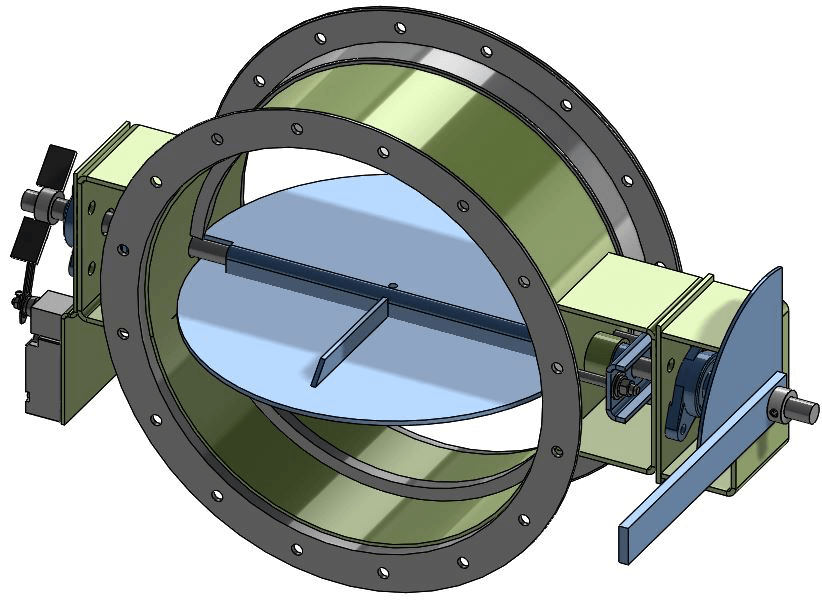

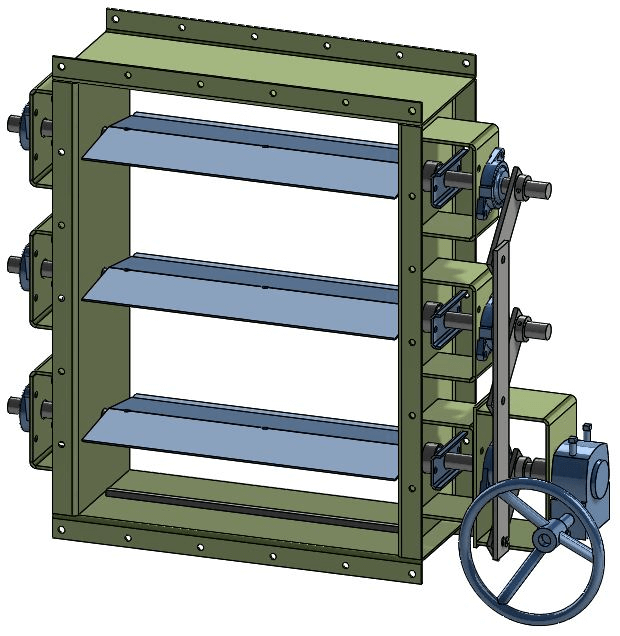

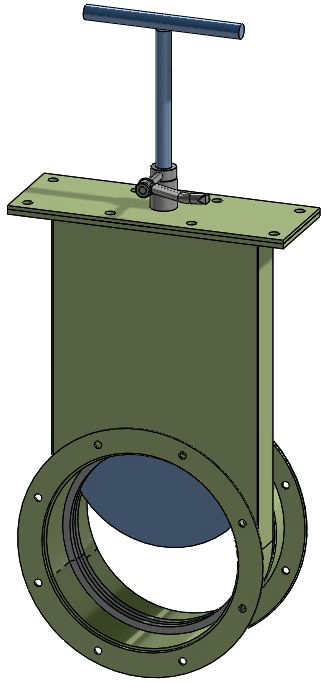

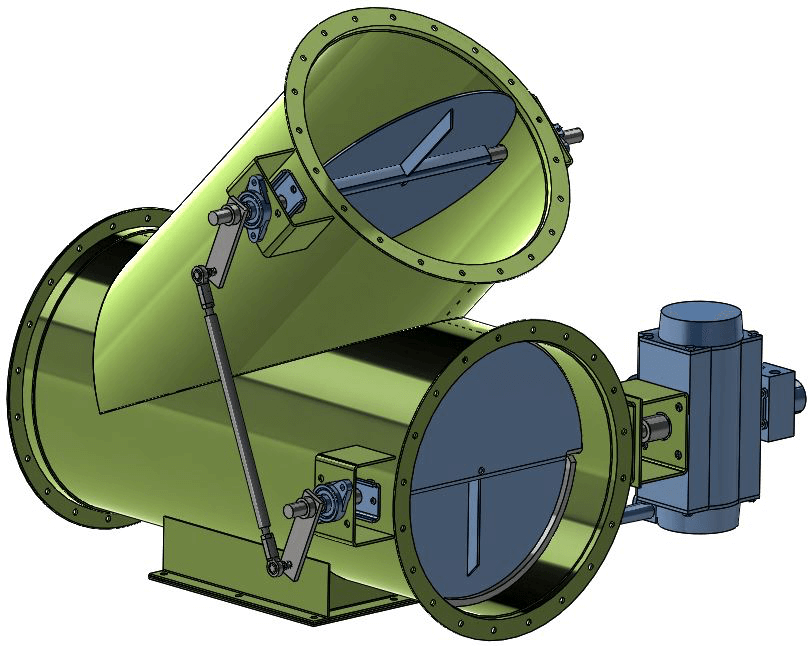

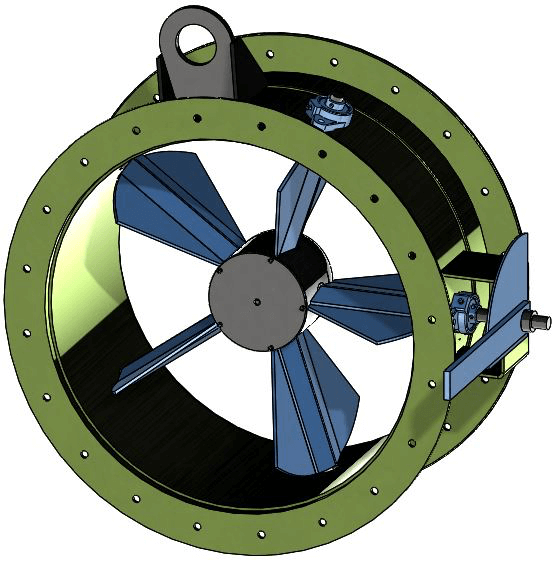

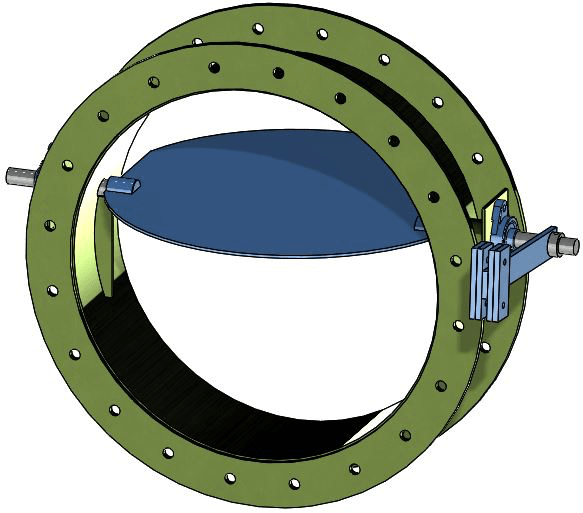

Industrial Dampers for Pulp & Paper Mills

Through the processing of bark, coal, and oil at pulp and paper mills, Kelair dampers are utilized in several capacities throughout this complex production for proper handling of water waste, sludge, and air pollution control in the pulp and paper industry.

Each stage of wood preparation, pulping, bleaching, and paper production requires a unique system of damper controls in the ductwork to move at desired flow rates in order to adhere to current environmental regulations on pulp and paper mill pollution. Managing the gaseous emissions demands precision at every step of the process. From the pulping and bleaching phases, to the sludge dewatering system, to the dust collection system – Kelair dampers and custom ductwork are made for your process.