Industrial Dampers 101

October 6, 2020At Kelair, we pride ourselves on offering a wide range of high-quality industrial dampers. Use the guide below for a high-level summary of our dampers and their diverse applications.

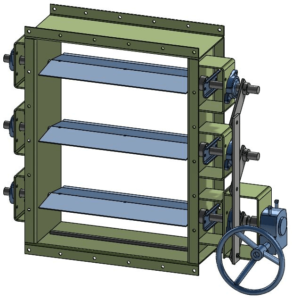

Louver Dampers

Kelair Louver Dampers or Multi-Vane Louver Dampers consist of several blades mounted parallel across a duct. They modulate the flow of air and gas in dry or wet conditions or can isolate and shut them off altogether. Opposing blade type louvers allow the flow to increase or decrease. Parallel blades allow for complete shut off and are particularly useful where space is restricted.

Kelair Louver Dampers or Multi-Vane Louver Dampers consist of several blades mounted parallel across a duct. They modulate the flow of air and gas in dry or wet conditions or can isolate and shut them off altogether. Opposing blade type louvers allow the flow to increase or decrease. Parallel blades allow for complete shut off and are particularly useful where space is restricted.

Louver Dampers can withstand temperatures greater than 1800°F (with refractory) and pressures up to 1 PSI, making them ideal for many different industrial processes. Parallel blade louvers are ideal for scrubbers, oxidizers, precipitators, fan inlets, atmospheric exhaust, along with gas turbine inlets and outlets. Opposed blade louvers are ideal for air filtration inlets (such as dust collectors), glass or metal tempering systems, fast power generation, and discharge outlets for fans.

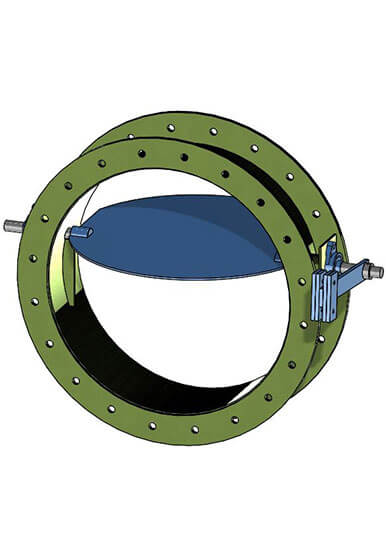

Wafer Dampers

Wafer Dampers (also known as Butterfly Dampers) are an economical industrial damper which can be used in most applications. Kelair’s Butterfly Dampers can also be engineered to process highly corrosive, abrasive, or high-heat air flows. These types of dampers can be a cost-effective means to control and isolate in air duct systems. Kelair’s Butterfly Dampers are applicable for open-closed service or flow control balancing.

Wafer Dampers are diverse in their ideal applications and are commonly used to control flow within low leakage and isolation applications. Wafer Dampers can be designed to withstand extreme pressures, and with refractory, can withstand very high temperatures as well (up to 1800°F). This gives them the ability to keep pressure drops low and efficiency high.

Diverter or Bypass Dampers

A Diverter or Tee damper is used divert the flow of air or gas within a system in another direction. It is typically arranged as a dual damper that resembles a Pipe-T, however it can also be configured at 45 degrees or as a “Pant Leg” version. The 2 openings or outlets are mechanically linked so that when one is opened, the other is closed. The use of one actuator with a slave linkage saves cost and assures simultaneous operation of both dampers in the assembly. Spring assisted actuators can be utilized to provide a predetermined fail position of the damper vanes.

Diverter Tee Dampers are commonly used within cogeneration units for waste heat recovery boilers. It is also common to use Diverter Dampers in air pollution control systems for gas power generation exhausts and heat recovery systems. Diverter Dampers are ideal to redirect high-temperature gasses or air from turbines to recover heat or to bypass a process in case of emergency to meet NFPA code.

Inlet Vane Dampers

The Inlet Vane Damper improves performance and efficiency within industrial applications. Vane Dampers pre-spin air, in the same direction as the fan rotation, before it enters the fan inlet. This directed air reduces the load on the fan by lowering the fan pressure and airflow. This in turn reduces the energy necessary to operate the fan. Inlet Vane Dampers reduce the energy costs necessary to operate fans, enhance their performance and provide long term savings.

Inlet Vane Dampers are ideal for facilities that need to have complete control of their ventilation; such as flue gas, automotive, and oven recirculation systems. They are also ideal to maximize fan life, reduce fan energy costs, and increase fan efficiency.

Guillotine Dampers

Slide Gate Dampers or Guillotine Dampers are a type of industrial damper commonly used when low leakage and low-pressure drop are required. They perform best where flow control is not critical but low leakage is. These types of dampers are well suited for situations where isolation of an airstream or gas flow occurs frequently due to routine maintenance, inspection, or repair.

Kelair’s heavy-duty construction allows for Slide Gate or Guillotine Dampers to function reliably in demanding environments with corrosive gas, particulates, and high temperature. These dampers are typically used in isolation applications such as scrubber inlet/outlet, flue gas clean up, isolation in the stack, precipitator isolation, and wastewater treatment facilities.

Backdraft Dampers

Industrial Backdraft Dampers allow airflow in one direction and prevent airflow in the opposite direction. Kelair’s Backdraft Dampers are manufactured to withstand environments with high back pressures and high airflow velocities.

Industrial Backdraft Dampers allow airflow in one direction and prevent airflow in the opposite direction. Kelair’s Backdraft Dampers are manufactured to withstand environments with high back pressures and high airflow velocities.

Backdraft Dampers have their niche in the industrial space, such as refineries, steel mills, and utility mills. This is because these processes require significant exhaust for their process, along with pressure relief and ventilation.

Have additional questions about choosing the right industrial damper?

Download our “Industrial Dampers 101” white paper and get in touch with a Kelair Products, Inc. representative today.