Backdraft Damper Installation: Best Practices

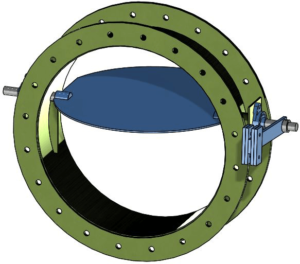

November 6, 2020Industrial backdraft dampers are an integral part of any ventilation system. Proper installation is essential—sloppy or improper work can lead to mechanical failures and even shorten your system’s lifespan.

When every dollar counts and the quality of environmental conditions within your facility are at stake, you need to assure that you’re getting the best work for your money. Being aware of and following best practices for industrial backdraft damper installation can make or break your industrial process and create safety hazards amongst your facility.

Preparation: Pre-Installation Testing

Preparation: Pre-Installation Testing

Industrial backdraft dampers often need to withstand extreme conditions and require formal testing before installation. At Kelair, we rigorously test our products to ensure they are up to ACMA standards.

Kelair also recommends pre-installation testing to evaluate the integrity of damper materials under specific environmental conditions, including high temperatures and high air pressure.

Testing should take into account the heavier weight of materials used to engineer backdraft dampers. Always make sure that the application’s framing can support the damper’s weight before installation.

Practice Good Material Handling

The installation process begins with safe handling of your new damper. It’s essential to take great care while unloading and handling your custom damper during installation. Failure to follow proper material handling practices can cause permanent damage to the damper, making it useless for its application.

Keep in mind the following:

- Make sure to use proper lifting devices such as a spreader beam or crane to avoid dragging or dropping.

- Never use a chain or a hook inside the damper’s frame as this can distort it and create problems in installation and operation. If applicable, use the lifting lug(s) provided on the damper.

- Avoid excessive force or uneven loads to the damper’s frame.

The Installation Process

Kelair manufactures a range of high-quality dampers. The process of installing each is unique and accounts for the various factors that may influence a damper’s integrity and effectiveness.

If you are currently installing a custom-made backdraft damper from Kelair and have questions about best practices or required parts, our team is well-equipped and can guide you through the process.

Testing and Creating a Maintenance Plan

For quality assurance, ask the following questions as a starting point for a post-installation inspection:

- Do the damper’s blade(s) fully close (automatically) from the open position?

- Is there any obstruction that could prevent it from operating as designed?

- Is system airflow verified to be within the velocity rating of the manufacturer?

- Is system temperature verified to be within the rating of the manufacturer?

Once the post-installation inspection is complete, maintenance checks should occur at least annually to ensure proper operation.

Be Confident with Kelair

The damper installation process can be intimidating, but Kelair works to simplify it by mastering the design and pre-installation process and always using the highest quality materials.

If you’re considering installing an industrial backdraft damper, in the middle of an installation of a Kelair damper, would like a site walk down, or have questions, contact us. We’re here to help!

Learn more about pre-installation testing and best practices in Kelair’s quality and performance standards guide.